UV LED CURING SYSTEM

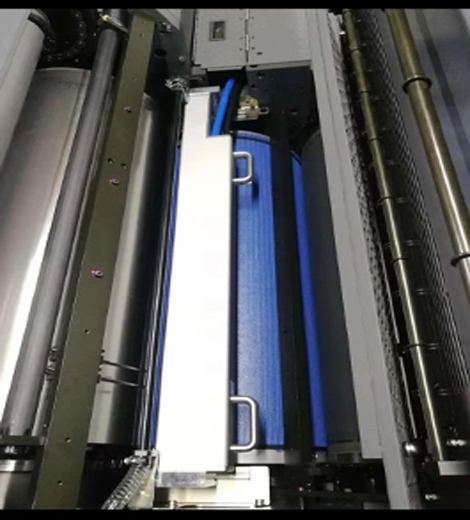

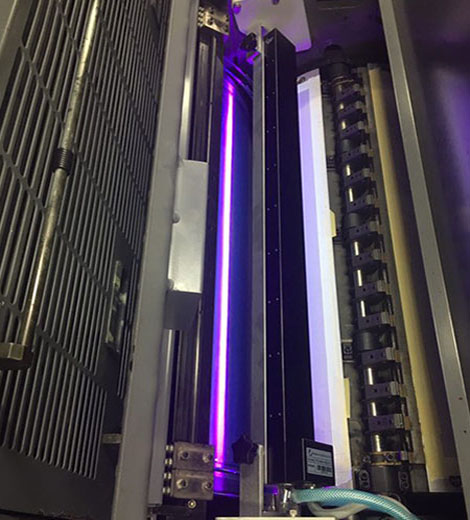

A clever modular basic concept combined with its extremely robust and compact design allows the user maximum flexibility and versatility. The system is freely scalable in length and can be adapted to all machine formats and installation situations. This makes it possible to use a UVLED unit at different positions on a machine. In combination with decades of experience in tailor-made machine integration, the compact design ensures the user access to important areas of the printing press at any time.

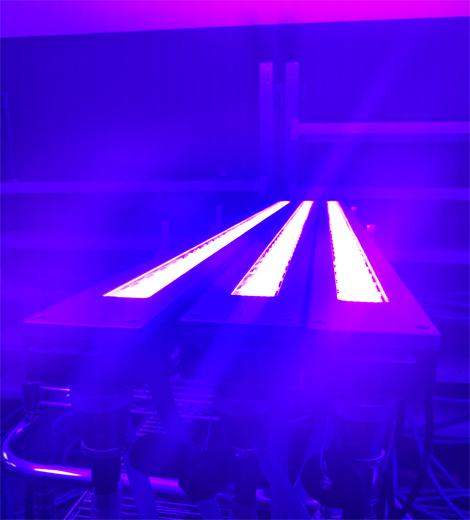

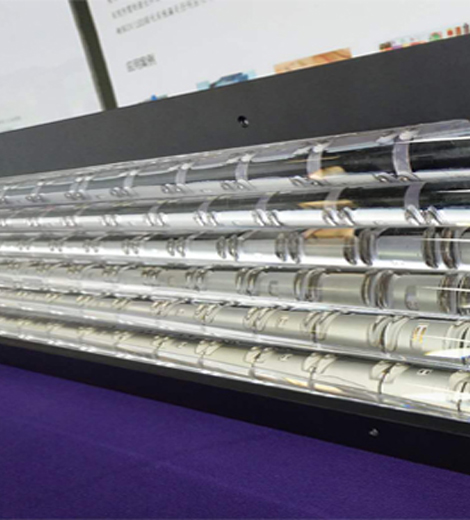

The UVLED has up to 20% more power than conventional LED systems. Other highlights of the new UVLED include the simple exchange of the optics or the possibility of retrofitting the LED chips.

Performance paired with flexibility

At the usual distance of 40 mm to 110 mm from the substrate, the new UVLED offers a very high performance in sheet-fed offset printing. This is not only due to the maximum irradiation intensity, the so-called peak, but the wide irradiation field of the UVLED also offers an extra drying time, also called dose. It is often as decisive for efficient curing of the LED colours and lacquers as the peak. As a result, customers and suppliers of consumables have more flexibility in the design and choice of paints and varnishes. Which states inks from various brands can be used for printing purposes.

Supported features such as width selection is also there to ensure extra power saving when printing smaller size jobs. E.g. 540mm,720mm,1020mm.