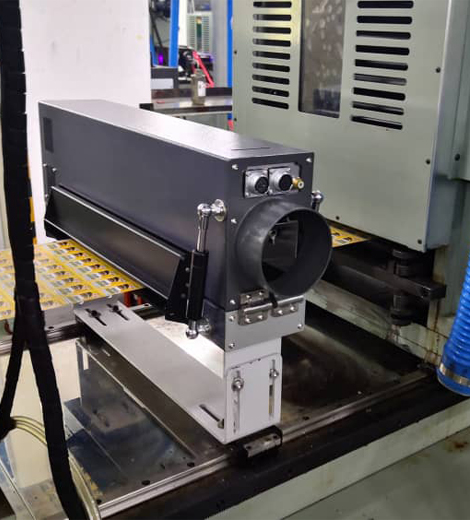

UV Curing systems for narrow-web/flexo machines

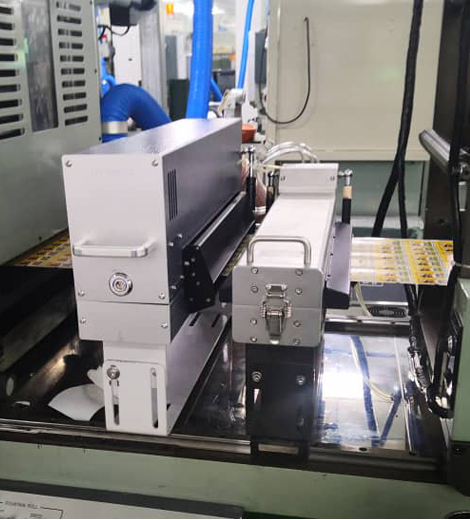

You can equip nearly every web press with a high performance UVLED curing system, whether it is a narrow or mid-web process. Due to the modular design (also with optional components), the UVLED unit will suit your every need.

Narrow web printing

- Seamless LED integration after each station

- Various labelling substrates are possible: from paper to shrink sleeves to unsupported films to metallic foil or even heat-sensitive materials like synthetics

- High speed up to 200 m/min (650 ft/min)

Easy and low-cost integration

Purchase just the LED components that you need for a tailored press integration. This saves you money on unnecessary accessories, services or components that you actually don't need.

Technical features such as, heat management, packing technology and the use of tailored driving technology ensure that the lifetime of UVLED units exceeds. Unlike UV lamp technology, UVLEDs can be switched on/off immediately which increases the lifetime and reduces energy costs in stand-by mode. UVLED curing units offer superior uniformity and a more reliable production process in contrast to UV lamps.

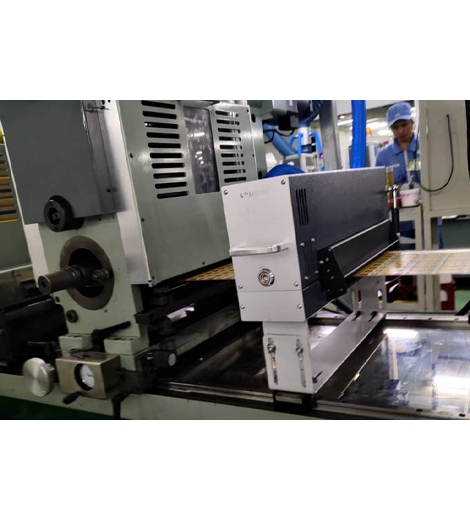

In general, LEDs generate a high heat load during operation, which is the main cause of lifetime reduction. That's why an excellent heat management design is so important to reduce the working temperature of the chips as far as possible.

Aligning the LEDs directly on the circuit boards, is still the best packing method, which will minimize the heat transfer. By adopting very high thermal conductivity materials in conjunction with water cooling, stable and precise output can be provided by the ideal working temperature of the chips, within 15–25 °C, that leads to a LED lifetime over 25,000 hours.